Thread tapping

Thread tapping/cutting involves thread turns being cut-shaped on bolts or in bores with multiple-edged tools.

Threads can be produced as:

– internal threads (female threads) with screwtaps

– external threads (male threads), e.g. with cutting dies

The tap cuts female threads in a component so a fastener can be screwed into it. The inner thread is cut from the inside of the material hole. The tap is selected according to the size and height of the thread.

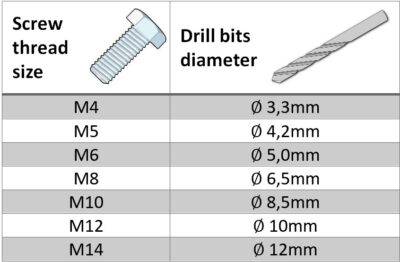

Before thread taping, it is necessary to determine the diameter of the hole and perform drilling. The diameter of the hole is determined based on the size of the screw we want to use. The size of the screw is denoted by the mark M. If we have a screw M8 multiply it by a factor of 0.8 and get the diameter of the hole in millimeters.

M8 x 0,8 = 6,4 mm

Drilling is performed with a drill bit of approximate diameter, in our case 6.5 mm.

There is a drill bit diameter table for the corresponding screw thread diameter:

Hole drilling is done at right angles.

Three screw-taps are used for threading:

– Taper tap (with one line)

– Intermediate tap (with two lines)

– Bottoming tap (without line)

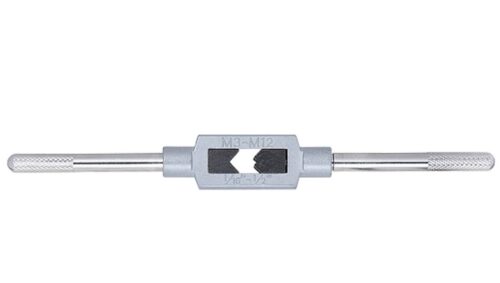

First, a taper tap is used which is placed in the tap handle:

Make sure that the tap is at a right angle to the material and the hole. The incision is made by turning the tap handle to the right (clockwise). During the taping, it is necessary to periodically turn the notch slightly to the left so tap the incised material is removed so that the notch itself is not damaged. The harder the notch material, the more often you need to return the tap. As soon as resistance is felt during the incision, we return the notch for a tap of the circle. Cutting oil is used for easier cutting.

When we cut a taper tap, we use an intermediate tap, and then a bottoming tap. Bypassing all three tapes through the hole, a thread was formed for the desired screw.

We test the correctness of the thread tapping by inserting a screw.

To perform the process of tapper thread cutting, follow these steps: