Steering systems

A steering system should ensure adequate quality of vehicle management. This function is crucial for driving safety and driver satisfaction. A good and high-quality vehicle control system reduces driver fatigue while driving.

Loose and worn parts of the steering system can cause incorrect steering, which causes the driver to turn the steering wheel continuously to keep the vehicle moving. A faulty steering system leads to premature driver fatigue. Also, when the power steering system is working, poor steering is difficult, which causes additional stress to the driver while driving.

If a component in the steering system fails and shuts down, the driver may lose control completely, leading to a vehicle collision and injury to the occupants

Mechanical steering system

Regular maintenance ensures a safe steering system. Also, any problems that arise must be diagnosed and fixed without delay. If the repair is not carried out in time or is performed incorrectly, there may be a loss of control over the vehicle and an accident. Therefore, follow the instructions from the vehicle manufacturer regarding regular inspection and repair of the steering system.

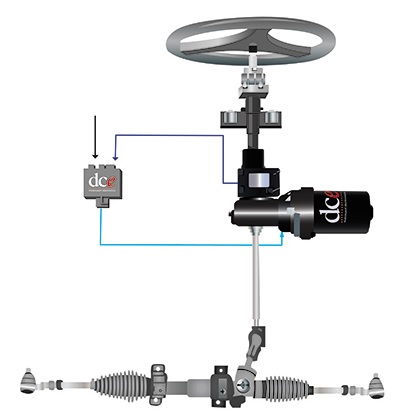

Steering systems are mostly mechanical, so visual inspections and physical measurements make up a good portion of maintenance and diagnosis tasks. Mechanical components wear out over time, reduce their functionality and eventually fail. But as more and more electronic power steering is introduced, electrical failures are becoming more common. The sensors are also subject to wear, resulting in inaccurate readings and incorrect reactions. Wires are subject to damage, breaks and loose or corroded connections.

Electronic steering system

When a problem occurs in the control system and performs diagnostics, it is important to consider both the mechanical and electrical components. Also, since the suspension system is directly connected to the steering system and helps keep the wheels in proper geometry, any suspension problems can affect the steering system. Thus, sometimes the cause of the steering problem may be due to some component in the suspension system.

When working on the steering system, be careful and pay attention to the following:

- Pay attention to rotating parts and belts while the engine is running.

- The power steering fluid can be hot during operation. Take precautions to avoid burns.

- Power steering systems can reach operating pressures of over 100 bar during operation. Always follow the vehicle or equipment manufacturer’s instructions when working on the system.

- The power steering fluid is flammable. Always keep it away from hot exhaust manifolds, pipes, or catalysts.

- The power steering fluid is aggressive and cleans up spills immediately.

- Wear suitable chemical-resistant gloves when working on hot systems