Flaring tools

The flaring tool is used to flare the end of a tube for better sealing when connecting to another tube or component. The tool widens the end of a tube to form a suitable shape.

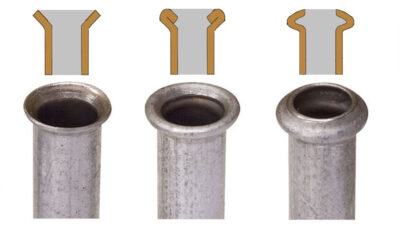

There are three different flange shapes:

– single flare, for lower pressures such as fuel,

– double flare, for higher pressures such as brake system and

– ISO flare, is the metric version used in brake systems.

Single flare, double flare and ISO flare

The flaring tool has two parts, a block with holes corresponding to the diameter of the tube being shaped and a yoke that redirects and pushes a cone into the mouth of the tube.

A special cutter is used to prepare and cut the tube. As the cutter rotates around the tube the blade point cuts the tube around the circumference. The screw increases the pressure, driving the wheel deeper and deeper through the pipe until it finally cuts through. After cutting with a file, smooth the upper surface and lightly fold the outer edge of the tube.

Tubing cutter

To make a single flange, the end of the tube is placed in the appropriate hole of the block. The end is aligned with the upper surface of the block and tightened the tube firmly in the block. Direct and press the conical insert over the yoke into the opening of the pipe, whereby the conical insert flares the end of the tube.

Making a double flare requires another step. The tube is placed in the hole and the end of the tube is raised above the bracket as much as defined by the tool measure. First, a bubble-shaped end is formed with the appropriate insert, and then a double flare is formed with a conical insert.

To obtain the ISO flare, only the first part of the previous procedure is used to give the end of the tube the shape of a bubble.