Charging the Air-Conditioning system

When the air conditioner does not work, the most common cause is an insufficient amount of refrigerant. The electronic system on the vehicle constantly controls the refrigerant pressure, and if it falls below the minimum value, it blocks the air conditioner from turning on.

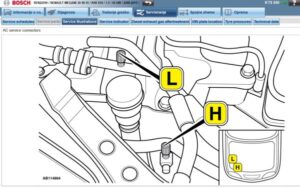

Before checking the amount of gas, the service technician first gets acquainted with the air conditioning system in the technical documentation for that vehicle. The necessary data for air conditioning servicing are the number and location of refrigerant connections, the type and amount of refrigerant, and the type and amount of oil. Also, it gets acquainted with the recommended procedures for testing and charging.

Checking the correctness and charging of the air conditioner, the service technician should use protective equipment (gloves, glasses) and adhere to the prescribed safety measures.

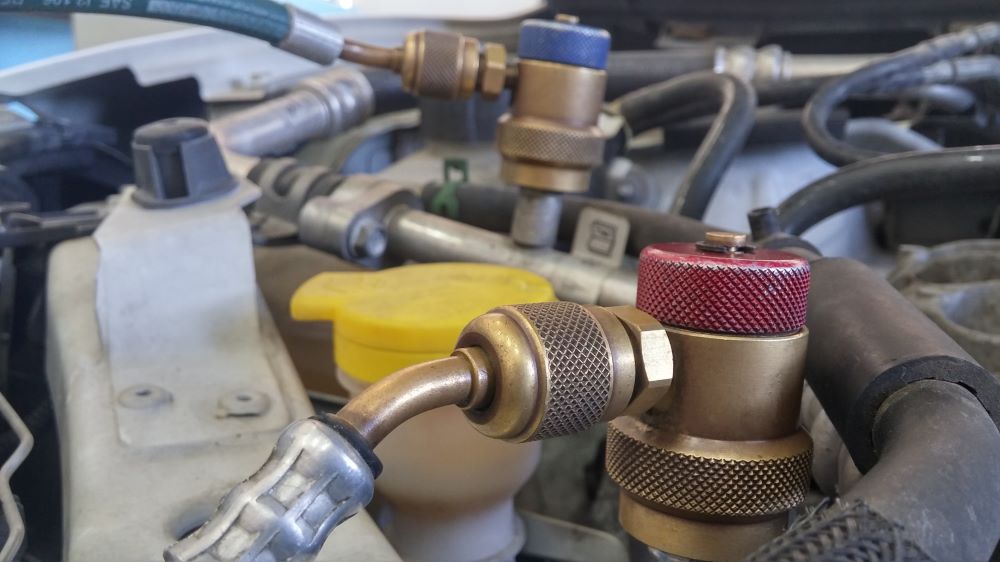

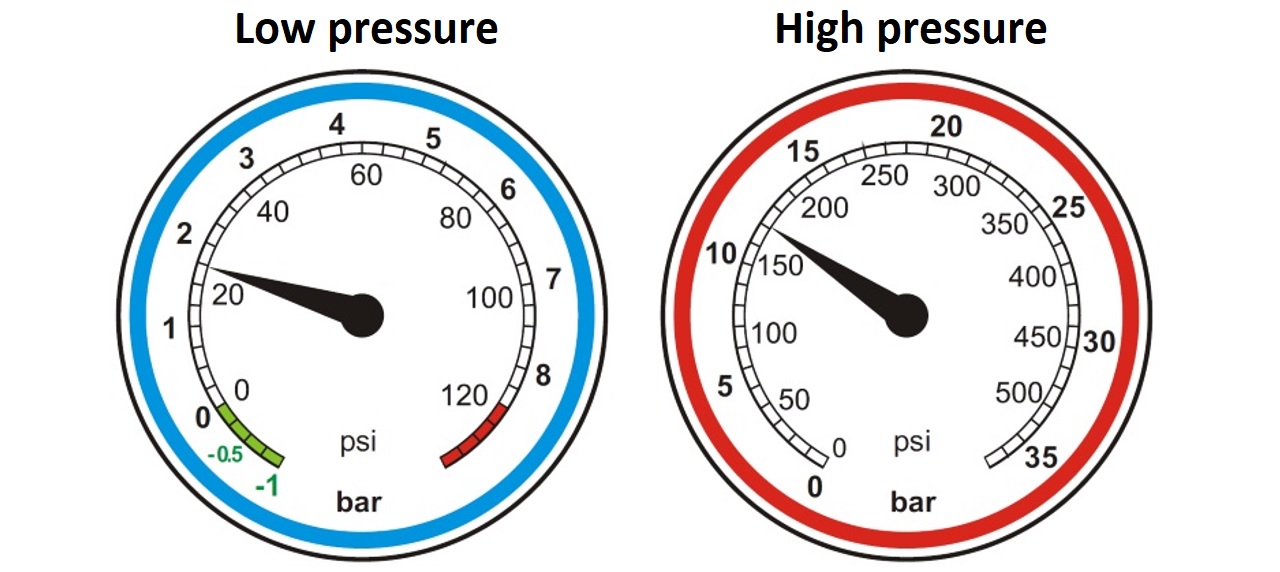

The air-conditioning station is used to check the pressure and charge. The AC station must contain the same type of refrigerant as the vehicle’s air conditioner. Different types of refrigerant must not be mixed. After locating refrigerant ports on the vehicle, the caps are removed and the connection to the AC station is made using hoses with special protective fittings. After connecting, the refrigerant from the air conditioner on the vehicle reaches the pressure gauge at the station.