Steering system visual inspection

A visual inspection of the steering system begins with a tire inspection. Check for correct pressure, construction, size, wear, and damage, as well as defects that include plying separation and sidewall knots. You should know that tire wear patterns are good indicators of problems with driving and hanging vehicles. Tire wear is also a great indicator that there is a problem with the alignment of the wheels.

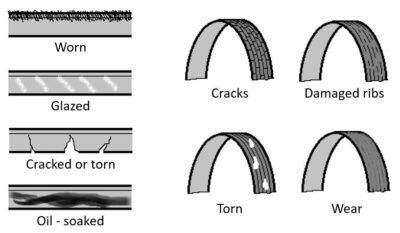

Tire wear patterns

After inspecting the tires, the condition inspection of the power steering drive belt, if equipped, is performed. The proper operation of the pump depends on the condition and tightness of the belt. The loose belt creates low pump pressure and difficult operation. A loose, dry, or worn belt can cause squeaking, especially during engine acceleration and cornering. The power steering drive belt is checked for tension, cracks, oil absorption, wear or smoothing of the edges, and tearing. If there is any irregularity, the belt should be replaced and adjusted properly.

Drive belt condition

Also, the level and quality of the servo oil are checked. The oil is checked at the servo pump reservoir using a dipstick attached to the reservoir cap. Before checking, find out whether the measurement is taken when the oil is cold or warm, or whether there are markings for both conditions. If it is checked when warm, let the engine idle for 2 or 3 minutes and turn the steering wheel from end to end several times. This warms the fluid to normal operating temperature and gives a more accurate reading.

Carefully examine the condition of the liquid. Check for evidence of contamination such as solid particles or water. If any of these conditions are present or the fluid has an unpleasant odor, flush the system.

Also, check if there is any air trapped in the fluid in the system. If the oil seems foamy, there is likely air in the system. To confirm this, run the engine until it reaches the normal operating temperature. Then turn the steering wheel to the left and to the right several times without rolling all the way. If there is air in the system, bubbles will appear in the power oil reservoir. Bleeding the system will remove the air.

Checking the power steering oil level

With the ignition off, wipe the exterior of the power steering pump, pressure hose, return hose, fluid cooler, and steering gear. Start the engine and turn the steering wheel several times from end to end for the pump to create oil pressure. Check for leaks. Fluid leaks will cause strange noises and may result in uneven and strained steering. If there are no signs of leakage at first, repeat the test several times. While doing this, look at the intestines for signs of bloating. Always replace power steering hoses with the correct replacement hose. Never attempt to repair or seal a leak at a hose or fittings.

Tie rod check

Carefully check all mechanical parts of the steering and suspension system. Many suspension problems can affect the operation of the steering system. Start from the steering wheel, through the transmission and rack to the end of the link. Make sure there are no loose, worn, or damaged steering system parts. It happens that problems with the steering system have a cause in the suspension system.