Rack and pinion replacement

Rack and pinion replacement is done after inspecting all parts of the system to ensure that the problem is in the rack assembly. Many symptoms, such as wear, play, and rough or uneven steering, can indicate a malfunctioning rack assembly. Regardless of the symptoms, all other steering problems should be considered and eliminated before removing or replacing the rack.

Because these systems vary by vehicle type and manufacturer design, there is no uniform removal and replacement procedure, so the following steps are non-specific. Before replacement, refer to service information and the appropriate repair manual.

After reviewing the service information, start the engine and straighten the wheels. After turning off the engine, it is necessary to lock the steering column (steering wheel). This will keep the clock spring in a neutral position after the post is released, as it will not be able to rotate freely and damage the spool. Lift the vehicle with a hoist, and remove the front wheels.

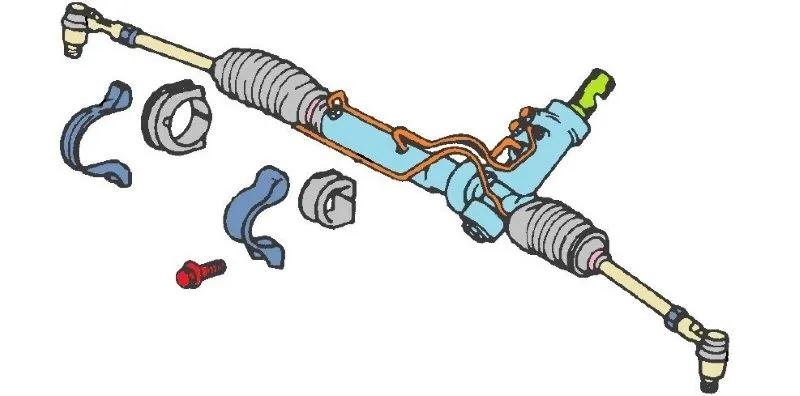

Removing and Replacing Rack and Pinion

First, the universal joint coupling is separated from the rack pinion shaft by removing the bolt or pin. If the same rack assembly is mounted, the coupling and pinion shaft are marked with paint before separation.

Then the hoses of the steering system are separated. Place an oil catch container under the power steering rack. Plug them to keep fluid from leaking.

After separating the steering wheel, move on to separating the outer tie-rod ends of the clamp from the knuckle. The cotter pins and nuts from the end of the tie rods are removed using an adjustable puller, fork, or hammer to remove the tie rod from the sleeve.

Finally, by removing the mounting screws of the bracket and bushings, the rack-and-pinion is released. Mark the position of the brackets and bushings if the same rack assembly is mounted. Due to its length, it is easiest to pull the rack-and-pinion assembly out through the vehicle’s wheel well.

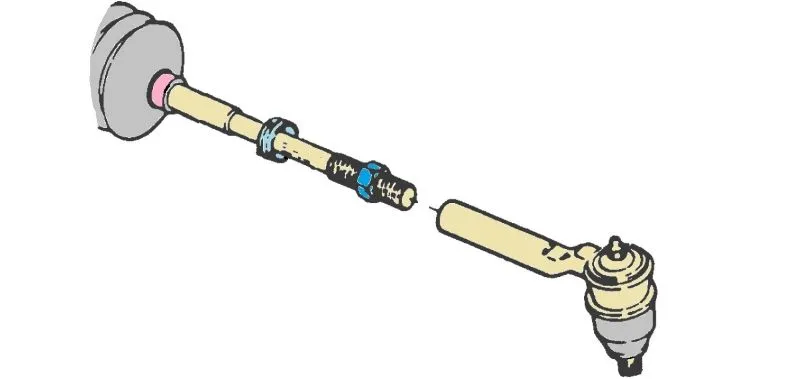

Tie Rods

When removing the tie rod ends for reuse, record the number of turns during removal.

An assembly of the rack is in reverse order. After mounting all the elements, it is necessary to perform wheel alignment.

Rack and Pinion Replacement Instructions

To rack and pinion replacement, follow these steps: