Engine vacuum testing

Engine vacuum testing involves measuring the vacuum of the intake manifold. The test is performed at different engine operating modes. A vacuum gauge (manometer) or an engine tester with a pressure sensor is used to measure the vacuum. The manometer is placed in the part of the suction line between the throttle valve and the engine at the existing connections of the vacuum hose.

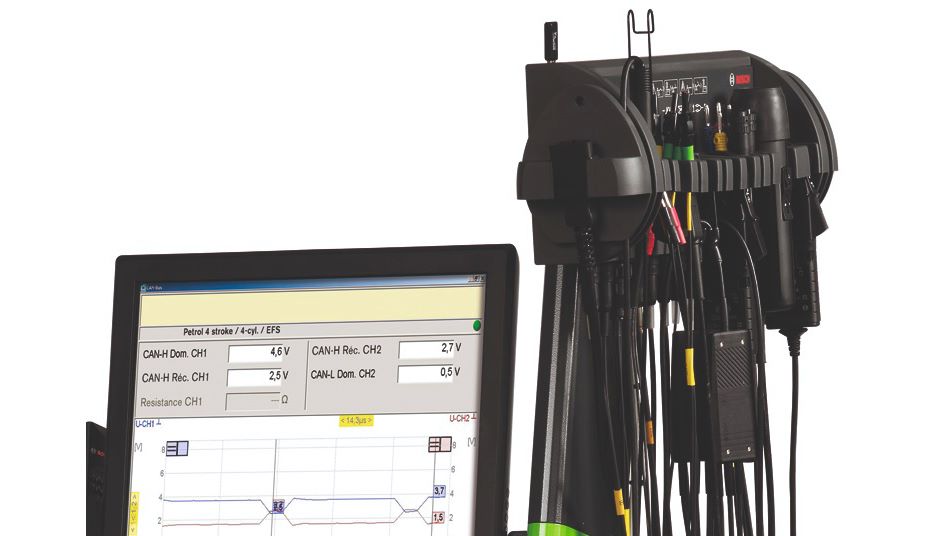

An engine tester is used for precise measurement and analysis of the obtained results. The pressure sensor is a very accurate meter. The measured values are displayed graphically on an engine tester oscilloscope. If the trigger monitors the ignition of the first cylinder, then each cylinder of the engine knows the value of a vacuum. In this way, a graph of the suction line vacuum values can be monitored, and how each cylinder functions in vacuum production and maintenance can be assessed.

With a correct engine, the intake pressure at idle should be in the range of 0.6-0.7 bar.

If the idling vacuum value constantly fluctuating in the range 0.15-0.3 bar, then the problem is in the ignition or poor closing valves.

When idling reads a constant low-value vacuum, then there is a possibility that the valves open late or late ignition.

When sudden acceleration in vacuum value falls to 0.7-0.8 bar, and it should be much higher about 0.9 bar, then there is a possibility that the piston sealing rings are worn.

In the event that we have the correct values at idle, and that at a constant engine speed of 2500 rpm the value of the vacuum slowly falls, there is a possibility of clogging in the exhaust system.

To perform a vacuum test of the engine with a manometer, follow these steps:

To perform a vacuum engine test using an engine tester, follow these steps: