Testing the vacuum check valve

When there is an internal vacuum leak from the power booster, one of the possible causes is a malfunction of the vacuum check valve. The power booster receives vacuum from external sources such as the engine intake line or vacuum pump. The vacuum is delivered to the power booster by a vacuum line.

The power booster should preserve the obtained vacuum until the first braking. However, the delivered vacuum can be lost through the same vacuum line in the opposite direction when the vacuum source has a higher pressure or when it is not working. That is why there is a vacuum check valve between the vacuum source and the servo device. The vacuum check valve passes the vacuum only in the direction from the source to the servo device. Blocks the opposite movement of the vacuum of power booster to the source.

A faulty vacuum check valve does not hold the vacuum and leaks it from the servo device, which results in a harder brake pedal and difficult braking. Testing is performed in two steps.

The engine is started for 30 seconds to fill the power booster with a vacuum. Wait 10 minutes after turning off the engine and remove the check valve from the power booster. After removing the valve there should be a strong rush of air into the power booster, which is a sign that the check valve is holding a vacuum.

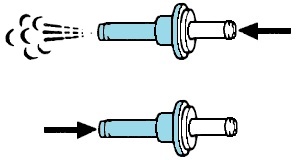

However, if there is no air surge after the removal of a check valve, a vacuum leaks from the power booster. A faulty check valve can cause a loss of vacuum. We remove the check valve and let air in or create a vacuum at both ends of the valve. The correct check valve should leak in one direction and block the movement of air in the other. If the check valve leaks air in both directions, should be replaced with a new one.

Testing the vacuum check valve

To testing the vacuum check valve, follow these steps: