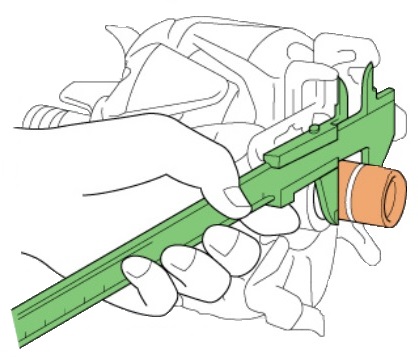

Slip ring inspection

Slip ring inspection is always performed when disassembling the alternator or when there is a malfunction in the power supply system. As the rotor rotates, the brushes touch the slip rings, ensuring the transmission of electrical energy to the rotor windings. Sparking and graphite dust lead to the burning of the ring. Dirt and burnt surfaces of the rings interfere with the flow of electricity and the operation of the alternator.

The surface of the sliding rings must be smooth, clean, and without burn marks. If rings are dirty and greasy, clean them up with a soft cloth and degreasing agent. When there are visible traces of burning on the surface due to sparking, the surface of the rings should be sanded with fine sandpaper that does not leave deep scratches. If the traces of damage on the surface of the rings are deeper so that repair is not possible, it is necessary to replace the rotor.