Checking and replacing alternator brushes

Checking and replacing the brushes is a regular process after dismantling the alternator or voltage regulator and when there are problems in the charging system. Brushes through the sliding rings and transmits power supply to the rotor windings. Power supply to the rotor windings and operation of the alternator depends on correct brushes. In the case of brushes, it is important that they have sufficient length, that the springs push them with a certain force, and that they slide easily in their holders.

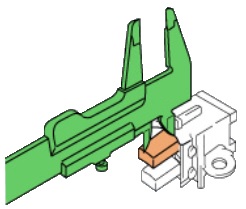

After removing the brush holder from the alternator, a visual inspection of the condition is performed. The brushes should be of equal length, the correct shape, and the holder should be undamaged and clean.

Bad brushes can damage the slip rings. Short brushes make weak contact with the sliding rings because the springs cannot press them with the necessary force. There is a high voltage drop and a weaker power supply to the rotor windings. The length of the brush is measured with a vernier caliper. The brush is correct as long as its length is 5 mm above the upper edge of the brush holder. If the brush is damaged or worn, they are replaced in pairs according to the specification for that alternator.